VibroBox and Smartbow are launching the collaboration

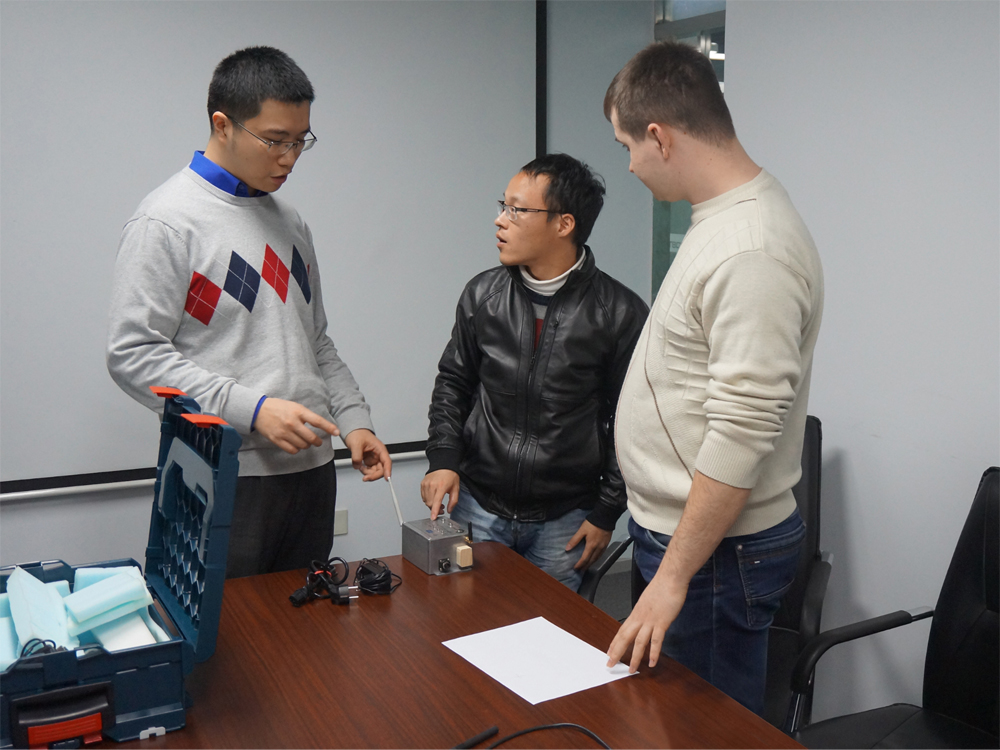

Siarhei Vasiukevich and Roman Tolkach with Smartbow colleagues.

Wind energy is one of the highest priority areas of Prescriptive Maintenance.

The complicated wind energy equipment operates continuously and autonomously, without maintenance personnel. The costs of its failure are very high. Prescriptive Maintenance by VibroBox minimizes financial and technological risks and increases return-on-investment (ROI) for wind farms.

VibroBox team actively promotes efficient maintenance for the wind power industry while China is one of the fastest growing and most important regional wind energy markets.

Smartbow is a Chinese company that operates in the field of structural monitoring of industrial and civil buildings, bridges and other structures. For this purpose, Smartbow has developed the specialized software platform with sensors and other hardware.

In 2017 Smartbow has entered the monitoring and diagnostics market of wind farms. To strengthen its market position, Smartbow is interested in sophisticated diagnostics and maintenance technologies targeted to a wind turbine equipment.

VibroBox technology aroused Smartbow interest in the fall of 2017, and joint activities in the field of interest were established. VibroBox specialists visited Beijing in December 2017 for a number of technical meetings and have deployed VibroBox system on a 2 MW Wind Turbine at a large wind farm in 270 kilometers from Beijing.

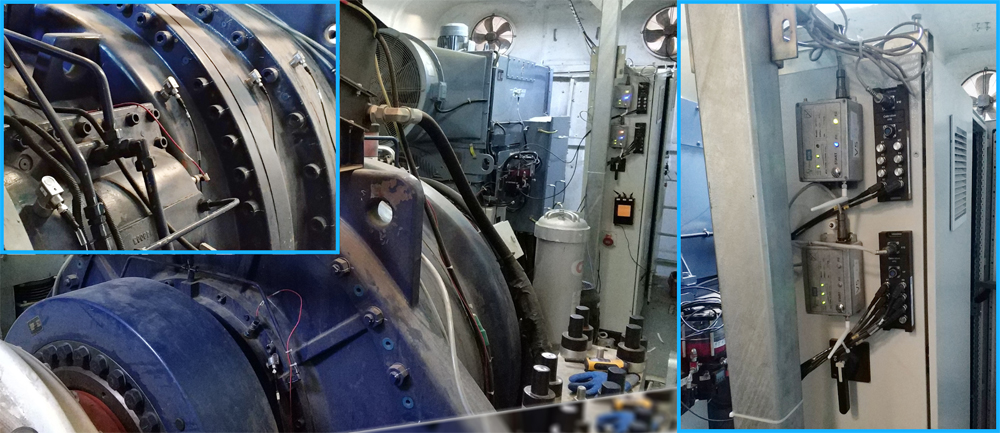

The installed equipment included:

- VibroBox VB1610 communication and telemetry data transmission unit - 2 units;

- ICP (IEPE) - VibroBox converter ADC1707-8 - 2 units;

- B&R accelerometer 0ACS100A.90-1 - 8 units;

- MikroTik wireless router RB912UAG-2HPnD - 1 unit.

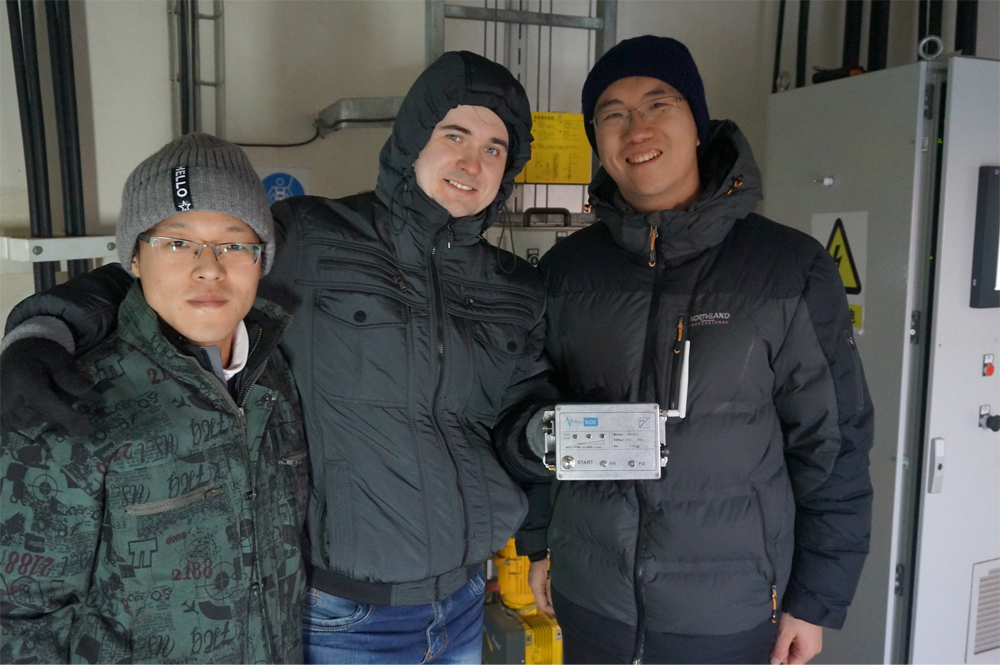

The successful deployment and testing of VibroBox system ensured Smartbow specialists in technology capabilities to provide efficient prescriptive maintenance. The next step for both parties is to conduct a large-scale pilot project on a wind farm in China.

Siarhei Vasiukevich explains how VibroBox hardware platform works.

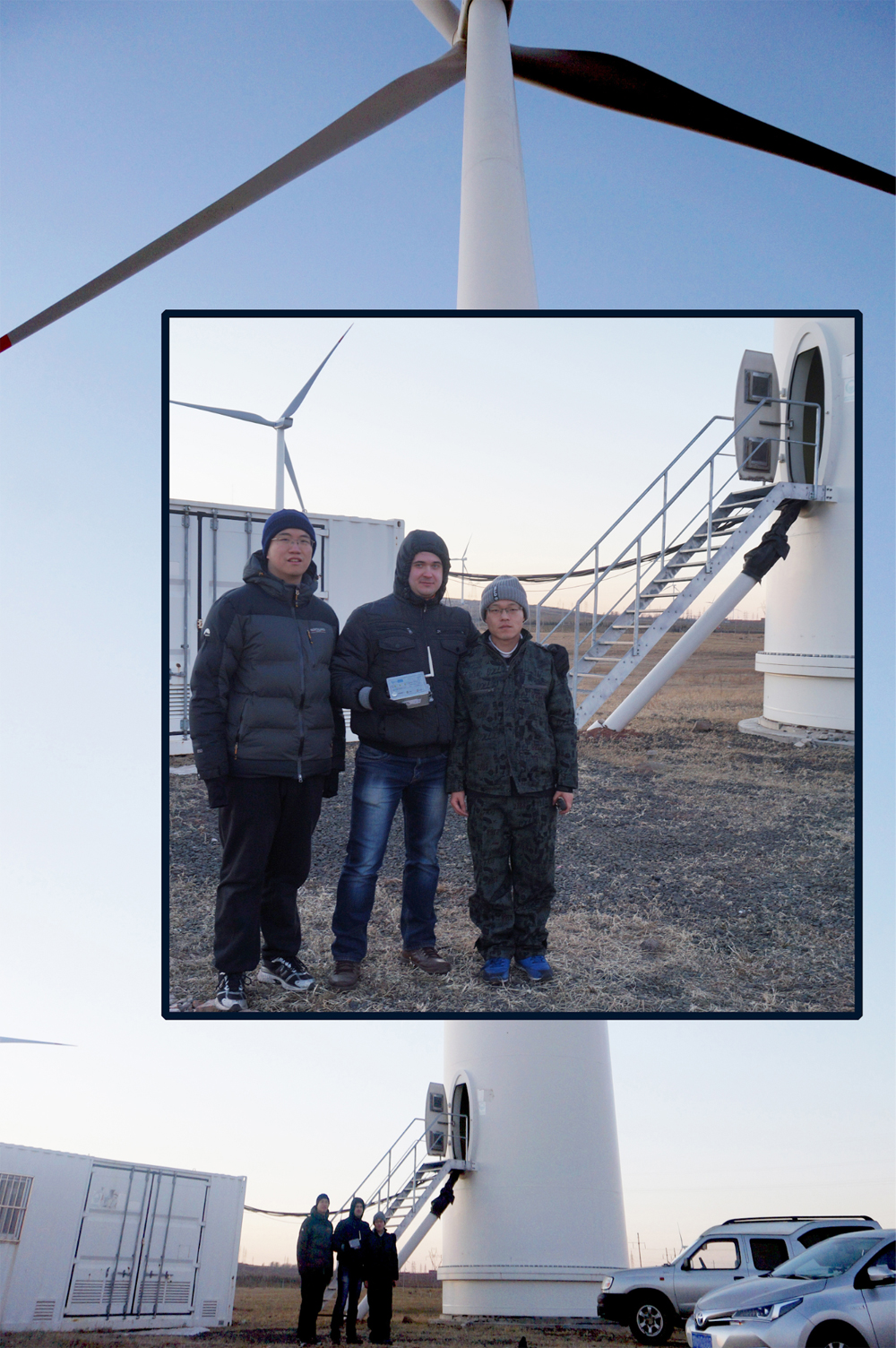

Siarhei Vasiukevich with Smartbow colleagues near the wind turbine where VibroBox system was tested.

Siarhei Vasiukevich with Smartbow colleagues and the view of the wind farm.

VibroBox hardware platform installation example.

Siarhei Vasiukevich with Smartbow colleagues.